DATA-CENTER Avtomatika

DATA-CENTER Avtomatika is a system integrator and solution provider specializing in the development of complex automation and production control systems at all levels. The company's product portfolio includes systems for monitoring and collecting quality indicators, virtual modeling and virtual reality, simulators of technological processes. Among the clients are large representatives of the metallurgical, machine-building, petrochemical and transport industries. The company's head office is located in Yekaterinburg.

What we did

October 2019 - December 2019

Yekaterinburg

Development of a system for visualizing the state of products

Background

In connection with the trend towards digitalization of manufacturing enterprises and the development of IoT technologies, DATA-CENTER Automation is developing its own platform for building solutions for the digitalization of an enterprise, DATA-TRACK. The modular architecture allows, when building a solution based on a platform, to supplement the final functionality by developing services that take into account the specifics of the production site.

To implement the platform at a Russian metallurgical plant, it was decided to develop a visualization service that takes into account the specifics of production. To implement this task, TAD Development was invited.

Project description

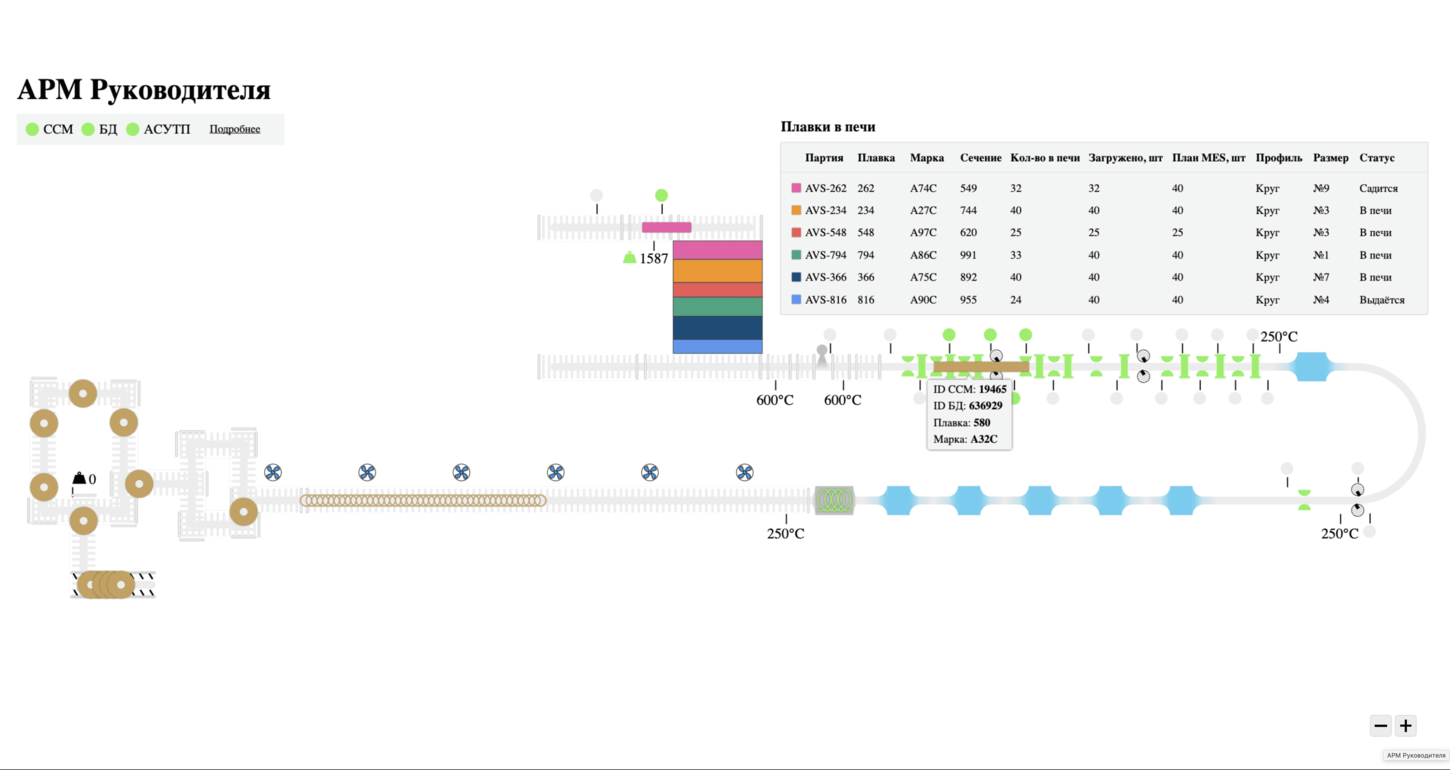

It was required to design and develop an industrial IT solution for visualizing the movement of products in the enterprise, so that all processes and stages of production could be “covered at a glance”. Thus, operators and managers will always be able to control the work in automated shops: from detecting defects and violations of production conditions, to analyzing the causes of failures and promptly solving problems.

Result

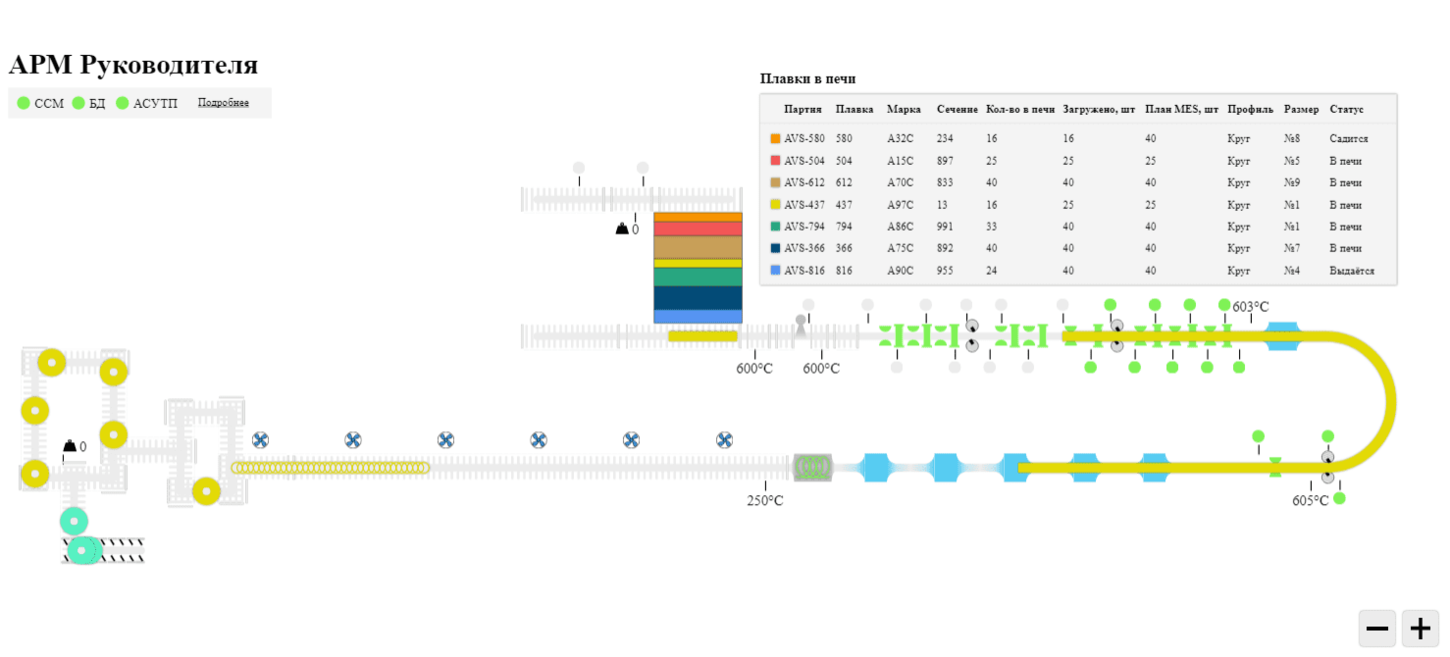

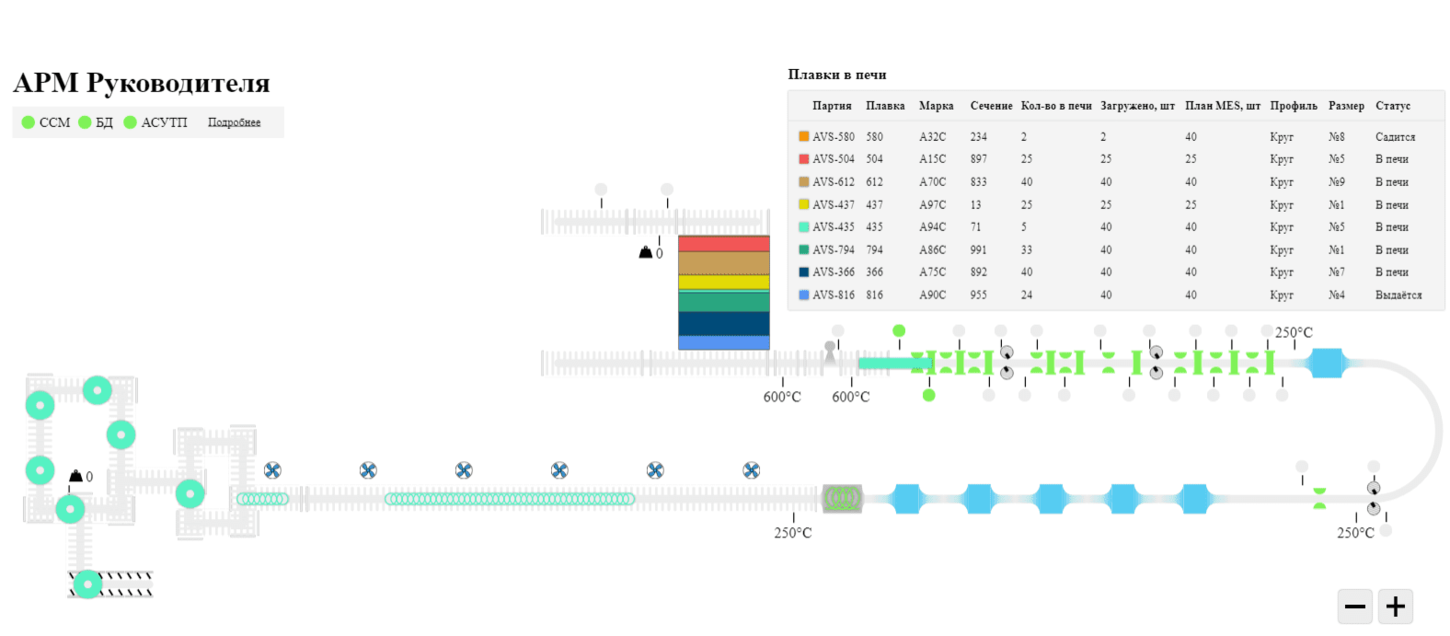

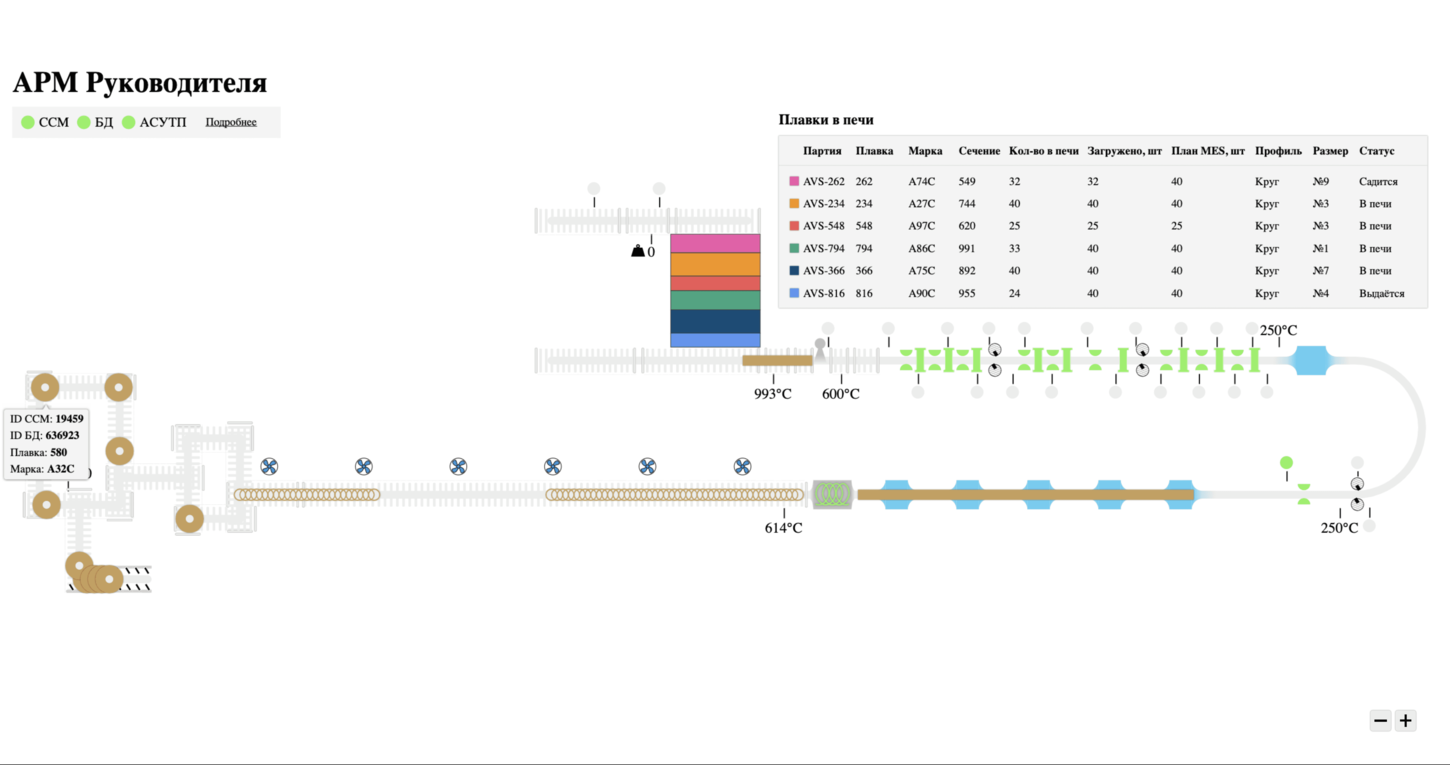

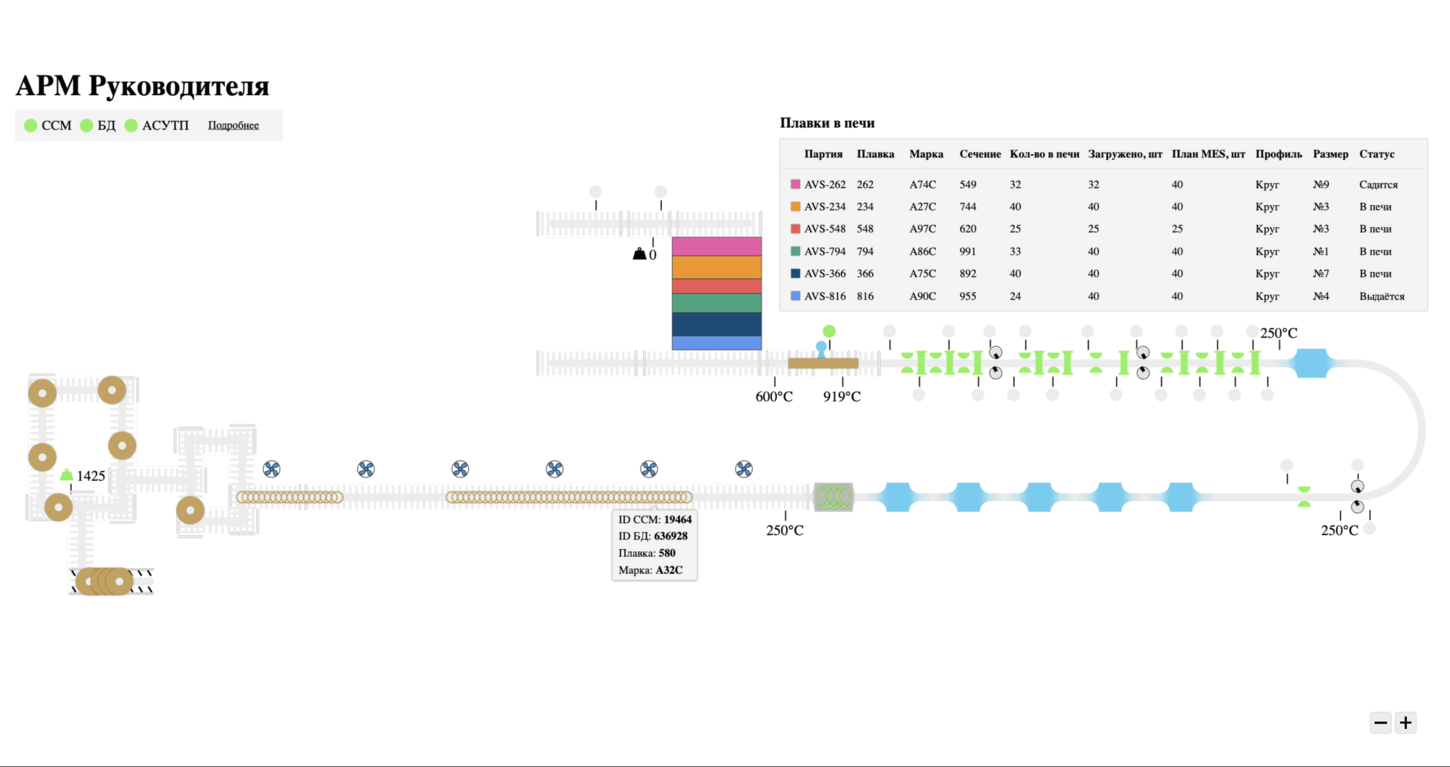

The functional interface, implemented in the form of a web application, allows you to monitor the status of products on the line in real time: from loading of raw materials to the release of the finished product.

The new solution is part of a comprehensive industrial analytics system. It collects information from various types of sensors located on production lines. As a result, complete and objective information is accumulated about all processes that occur with equipment, products and production in general.

Visualization of all processes and parameters of production lines: the state of equipment and external integration systems, the temperature of functional units and the schedule of its changes in real time, the mass of products when passing the scales at each stage of processing, and much more. The system tracks the movement of all products, displays information on their identification, the number of blanks and finished products. All this in a single digital ecosystem.

The “smart” solution provides full control at each technological unit of production, minimizes human intervention and the error probability.

Technologies

Contact Us

If you have an idea, contact us - we'll find a way to bring it to life!